Manufacturer Medical Equipments Since 1999

Circle Absorber

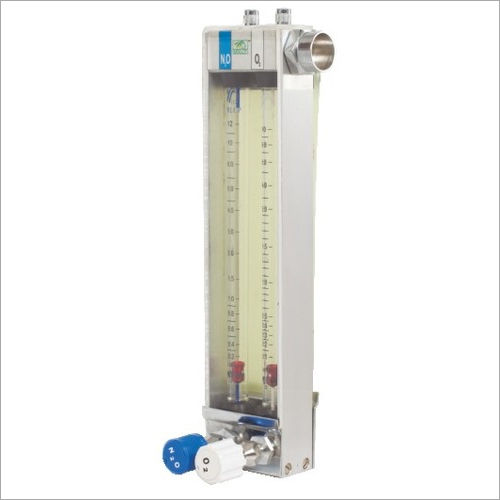

Product Details:

- Temperature Range 0C to 50C (Recommended)

- Power Manual (Non-electric)

- Properties Precision gas absorption, autoclavable parts

- Application For Hospitals Use

- Weight 1-5 Kilograms (kg)

- Material Stainless, Glass and Plastic

- Shape Round / Cylindrical

- Click to View more

Circle Absorber Price And Quantity

- 10500 INR/Piece

- 1 Piece

Circle Absorber Product Specifications

- High

- Stainless, Glass and Plastic

- Circle Absorber

- For Hospitals Use

- 1-5 Kilograms (kg)

- Precision gas absorption, autoclavable parts

- Closed and semi-closed circuit anesthesia systems

- Manual (Non-electric)

- Single Phase

- 0C to 50C (Recommended)

- Approx. 1.6 liters (absorption canister)

- 150 mm (approx)

- Absorption of exhaled CO2 gases in breathing circuits

- Operation theaters, medical centers

- Manual

- None required

- Silver / Transparent / Blue

- Anesthesia gas filtration

- 270 mm x 200 mm x 150 mm (approx)

- Round / Cylindrical

Circle Absorber Trade Information

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- 20 Piece Per Week

- 1 Days

- No

- All India

Product Description

Circle Absorber

Owing to our decades of experience in the domain has enabled us in offering an international quality standard of Circle Absorber. Manufactured with utmost precision, these absorbers are widely appreciated among our clients for attributes like leak proof quality, easy cleaning and efficient performance. Our circle absorber system, circle absorber anesthesia enables significant reductions of the consumption of oxygen and safely anesthetics in open systems. Furthermore, we also offer these absorbers at a nominal price.

Specification:

- Transparent Light weight canister.

- Double Chamber Adult size.

- Soda lime Capacity 1800 gms.

- fully autoclavable.

Reversible Soda lime canister fitted to control head by means of a central tube which is screwed into the head with a large plastic hand wheel.

Precision Gas Absorption Technology

The Circle Absorber employs advanced gas absorption technology, ensuring effective filtration of exhaled CO2 during anesthesia procedures. Its high-accuracy design guarantees reliable performance, making it an ideal choice for maintaining patient safety and procedural efficacy in demanding clinical environments.

Seamless Maintenance and Sterilization

Featuring a user-friendly design, the absorber's canister is easily replaceable, simplifying routine maintenance. All critical parts are autoclavable, enabling thorough sterilization between uses. This supports strict infection control standards crucial in modern medical settings.

Universal Compatibility and Robust Construction

Built with standard breathing circuit connectors, the Circle Absorber integrates effortlessly with most anesthesia systems. Its durable combination of stainless steel, glass, and plastic resists corrosion and damage, guaranteeing longevity and reliability during continuous use in hospitals.

FAQ's of Circle Absorber:

Q: How should the absorbent canister be replaced in the Circle Absorber?

A: To replace the absorbent canister, first ensure the device is disconnected from the breathing circuit. Open the compartment containing the canister, remove the used absorbent, and insert a new canister filled with compatible soda lime or equivalent material. Securely close the compartment and reconnect the device to ensure a proper seal.Q: What sterilization method is recommended for the Circle Absorber's components?

A: It is recommended to sterilize all relevant parts of the Circle Absorber using an autoclave. This ensures thorough disinfection, maintaining a safe and hygienic environment for patients undergoing anesthesia procedures.Q: When should the absorbent material in the canister be replaced?

A: The absorbent should be replaced when it reaches its exhaustion indicator or as advised by the manufacturer, typically after prolonged or repeated use. Regular monitoring is important to ensure effective CO2 absorption and patient safety.Q: Where can the Circle Absorber be used effectively?

A: The Circle Absorber is designed for use in hospitals, especially within operation theaters, medical centers, and any facility utilizing closed or semi-closed anesthesia systems. Its universal connectors make it suitable for integration with most anesthetic workstations.Q: What process does the Circle Absorber use to remove CO2 from anesthesia circuits?

A: The Circle Absorber utilizes a chemical absorption process with soda lime or equivalent media. As exhaled gases pass through the canister, CO2 is removed, allowing rebreathing of anesthetic gases while maintaining patient safety.Q: What is the main benefit of using this absorber in anesthesia systems?

A: The primary benefit is precise and effective removal of exhaled CO2, which enhances patient safety, supports high procedural accuracy, and reduces the consumption of fresh anesthetic gases during operations.Q: How does the Circle Absorber ensure minimal flow resistance and leak prevention?

A: The absorber is engineered to keep flow resistance below 2 cm H2O at 60 L/min and maintains a leakage rate of less than 0.1%. This design supports unfettered airflow within the system while minimizing any risk of gas leakage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+